A Jazz bass in for a fairly standard setup with low action. One issue I discovered while changing strings was that the string ferrules in the back were super loose and fell out onto my bench. Not a good thing as they can be easy to loose if you are not paying attention. Similar to refitting peghead tuner bushings, I used some superglue snug them up. Note that I do NOT glue the ferrules in. The cured glue is used to add back material to the holes and give the ferrules something to bite into. I often opt to add glue to the tuner bushings but on these ferrules I opted to add glue to the holes in the body.

Viewing entries in

repair

Bleep, blop, bloop! A Gibson 1st production run "Robot Guitar" in for a setup. What makes it a robot? It can tune itself automatically. Just pull the grey knob, select the tuning, press the center button, pluck the open strings and the tuning knobs take care of the rest. Certainly a novelty guitar but the auto tuning works fairly well. Sometimes it doesn't find the pitch on the first pluck but just hit the string again until the knob light of corresponding string turns green. A concern I would have on these guitars would be the availability of the proprietary Tronical tuning system components should something fail. Both the bridge and the stopbar are part of the system along with the motorized tuners and circuit board.

An early 90's Strat in with some electronics issues. The output was completely dead so I popped off the jack plate and found a broken connection that needed to be resoldered. A fairly standard issue repair on Strats. Another issue was that this player's neck pickup had been acting up for some time and finally cut out him. When I pulled the pickup I found that the inside coil lead had been cut. The flatwork looked like a cutting board where a nick perfectly matched the break. A fellow local tech and pickup winder friend of mine, Chris Tatoyian of Black Cat Guitar, told me of a great fix he has used in the past. Since it is the inside wrap, I can't unwind the pickup and resolder to the pickup lead. His fix is to use copper shielding tape and make a soldering pad on the flatwork. Total genius! This trick saved the pickup from having to be rewound or replaced. You rule Chris!

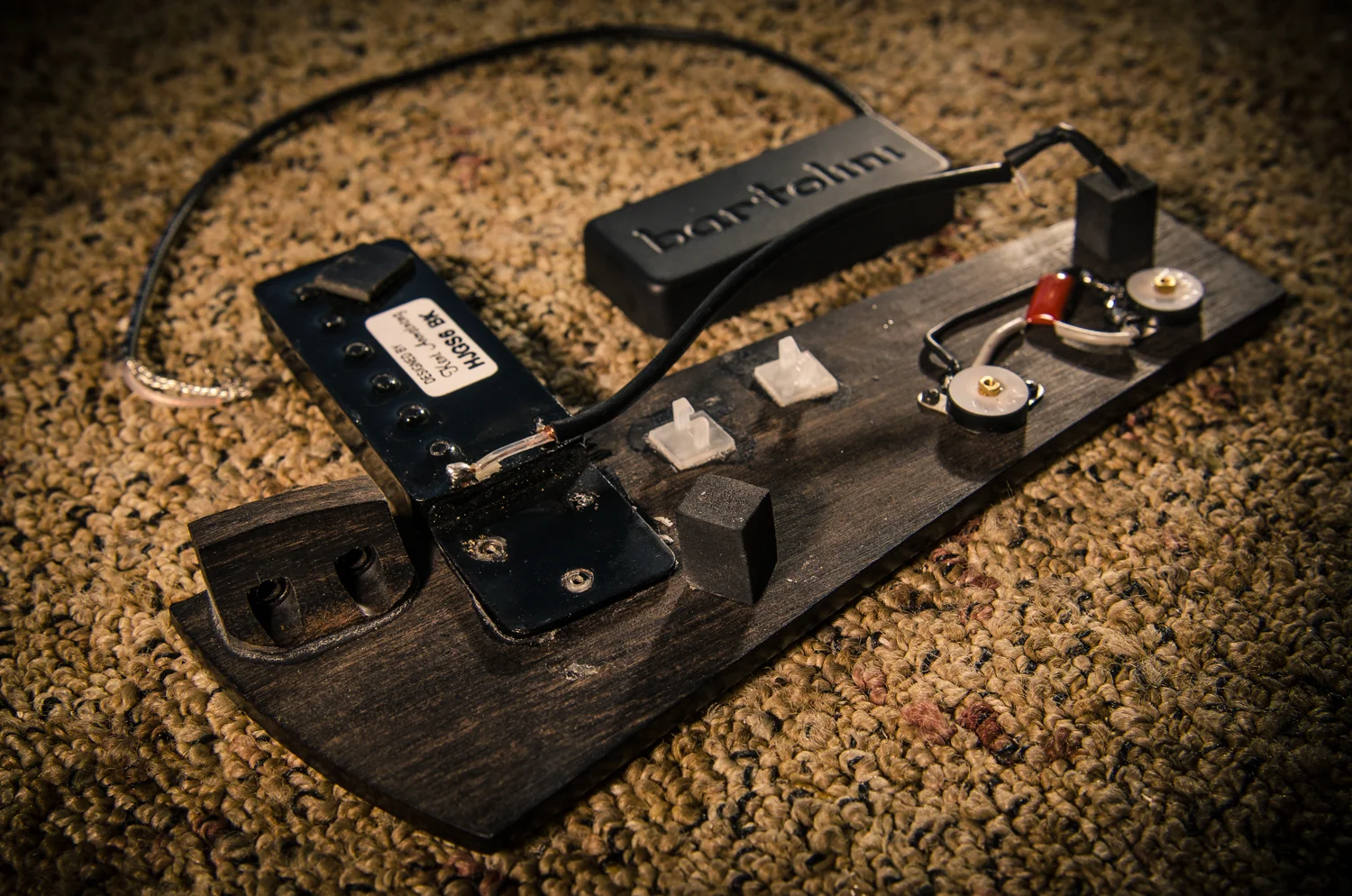

A noisy pickup that needs to be replaced. This pickguard assembly is super clean, but the pickup is epoxied and screwed to the ebony making it difficult to remove. The tiny screws stripped and/or broke on me so out comes the heat lamp to soften things up. Aluminum foil helps direct the heat to only the pickup mounting tab, though some heat does transfer via the metal tab to the pickup. Not a big deal since the pickup is bad.

A 70's style Strat back in the shop to complete it's Lowell George-esque setup with a Tele bridge pickup and Alembic Blastor preamp. Above the body is being routed out for a Seymour Duncan Tele bridge pickup. I forgot to photo the method used to enlarge the bridge in the pickguard (yes, a Tele bridge pickup is bigger than a Strat pickup). What I did was to take a Tele bridge, double-stick taped it to the pickguard and used a violin knife to pare away the excess. It worked fairly well.

The owner found a NOS original Blastor from the 1970's (not the newer Blaster / Strat-o-Blaster). Pictured above is the back of the body is being routed out to accept a 9V battery box to power the Alembic preamp. A battery box is not required, but it's nice to have easy access. You can install the battery under the pickguard but it can be a pain having to take off the pickguard for each battery change. I would not install a battery box on a vintage instrument. Also note that we ended up lowering the action at the nut considerably from last time it was in.

![Loose ferrules & setup :: 2011 Fender Jazz Bass [8.8 lbs]](https://images.squarespace-cdn.com/content/v1/53dfcee2e4b0c0da377c65c7/1457666702608-2BK5C96XCNFO5O8YQU83/20160310_2011_Fender_Jazz_bass_ferrules.jpg)

![Setup :: 2007 Gibson Robot Guitar [8.0 lbs]](https://images.squarespace-cdn.com/content/v1/53dfcee2e4b0c0da377c65c7/1457247854395-3QVV28NUCEKYGUA9N0KC/image-asset.jpeg)

![Dead pickup quick fix :: 1991 Fender American Standard Stratocaster [8.5 lbs]](https://images.squarespace-cdn.com/content/v1/53dfcee2e4b0c0da377c65c7/1457167453062-C9TB09JAMWWK6C9DLSC9/image-asset.jpeg)

![Lowell George setup :: 2001 Fender Stratocaster [7.5 lbs]](https://images.squarespace-cdn.com/content/v1/53dfcee2e4b0c0da377c65c7/1456387850900-NU41WBIMVZD1JGJQEGS7/image-asset.jpeg)