A common acoustic repair shown here is damage to the sound hole. This section was broken in two places and hinged at the rosette's inner ring. The fix is to fit and glue a supporting cleat inside the sound hole. Once I make the cleat, I like to glue the break and install the cleat in one shot. For bonus points, I also slightly age the new cleat so it looks like an older repair.

Viewing entries tagged

clamp

The fret ends all along the fret ends were loose and lifting so I hammered them back down. This fret was stubborn and would just pop back up like a diving board so it needed to be glued and clamped into submission.

A Garrison dreadnought cutwaway with a split heel. The neck construction is a 5 piece stacked heel and the heel cap laminate is split through the glue joint. This is a bolt-on where the lower threaded insert in the heel lands dead-center of this glue joint and has separated the two. I worked in some glue and closed the joint with a clamp.

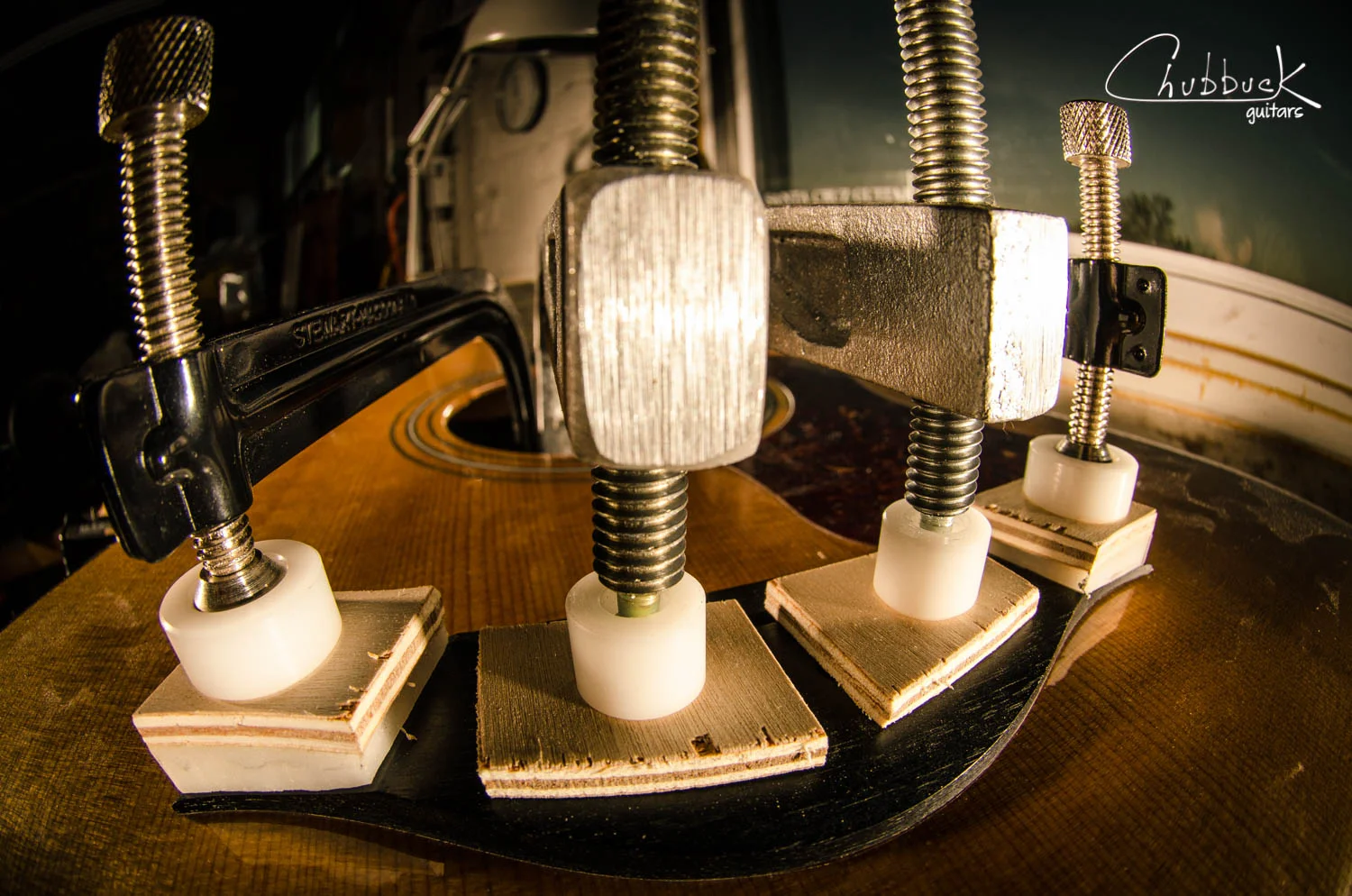

2001 Taylor 310 :: bridge re-glue

Early pre-dawn bridge re-glue on a Taylor 310 dreadnought. I'm loving the moldable plastic pellets (InstaMorph) I picked up weeks ago for making custom clamping cauls. The cauls are shown above on the outer wings, backed with plywood for rigidity and to keep the clamps from slipping.

Loose frets :: 1960's Teisco May Queen

Just about every fret end on this neck is "sprung" and needs to be glued and clamped back down. Not ideal, but it will hopefully make it more playable and save the player some cash on a total refret (which it could use as the frets are fairly low).