A late 70's Ibanez Artist on the bench for a setup. The output jack plate has a mounting screw that was broken flush with the wood that the customer wanted addressed. I used my shop made screw extractor to remove the screw and plug the hole. The hole is then drilled to accept a fresh screw. Click here for more details on another project involving broken screw removal.

Viewing entries tagged

broken screw

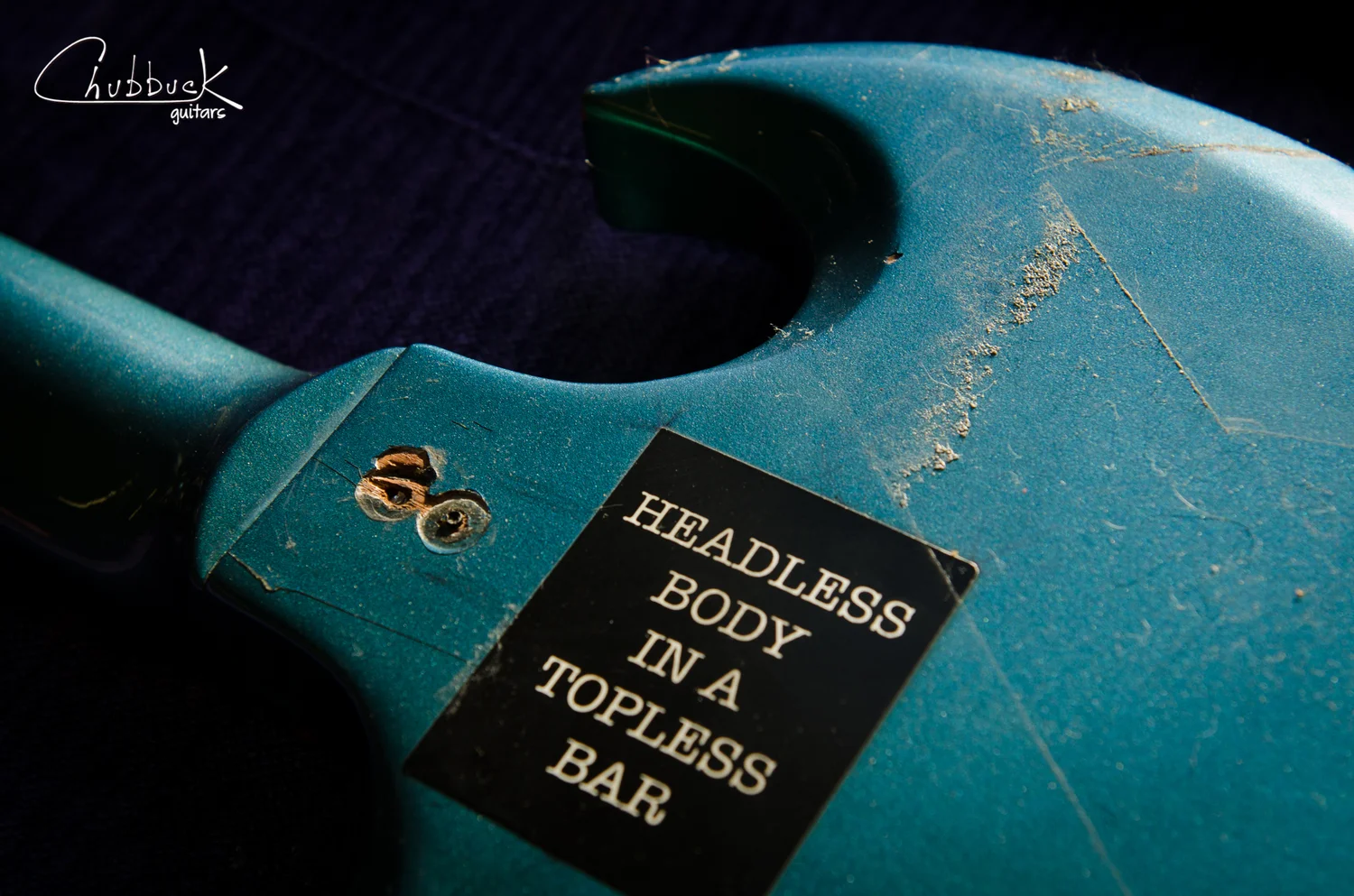

2001 Gibson SG :: broken screws

I needed to fabricate a couple custom screw extractors to cleanly remove two broken strap button screws. The extractors are made from stainless steel tubing sized to fit over the screw with teeth cut into the end. I sourced the tubing from McMaster-Carr. The extractors are run counterclockwise in a drill to not risk driving the screw deeper if it grabs. The broken screws can be seen here.

Look for a blog post coming soon with more details on this guitar.

2001 Gibson SG :: broken strap button screws

This SG has been in the shop a few times before for a broken control cavity and to correct a failing headstock repair. Now it is in for a broken strap button screw. Actually, two broken screws as one was broken before. I'll need to make a couple different size screw extractors to get these out.

Look for a blog post coming soon with more details on this guitar.

Schecter Stiletto Studio 5 [9.2 lbs] :: setup & tuner tweak

This neck-though 5 string bass came in for a setup with Rotosound Stainless roundwound strings. Upon inspecting the bass I found the D tuner had some play to it. I removed the tuner to find that the mounting screw was bent and ready to break (pain to remove when they break) and the screw hole stripped out. I plugged and re-drilled the hole and replaced the screw.

Note that the tuners on the end of the headstocks tend to receive the most abuse due to their exposure. Gig bags can sometimes be rough on these tuners as well.

Broken tuner screws :: custom shop-made headless screw extractor.

![Broken screw & setup :: 1977 Ibanez 2618 [9.4 lbs]](https://images.squarespace-cdn.com/content/v1/53dfcee2e4b0c0da377c65c7/1479273003129-UHLZAD0RVDNLAC96ZMLK/20160831_1977_Ibanez_Artist_2618_bench.jpg)

![Schecter Stiletto Studio 5 [9.2 lbs] :: setup & tuner tweak](https://images.squarespace-cdn.com/content/v1/53dfcee2e4b0c0da377c65c7/1430980588718-OR1K14C6AC83WT0YOC9P/image-asset.jpeg)